|

Sushmita Singh Research Scholar Institute of Management, B.H.U |

Prof Raj Kumar Director Dean & Head-Institute of Management B.H.U |

Handloom weaving is an age old craft which is passed from one generation to another as a family legacy which makes it like family business but lack of proper management skills such entrepreneurial skills this profession is not getting its due recognition resulting in a situation where this art is almost on the verge of extinction. But the younger generation is not very keen to continue this family occupation due to lack of recognition, low wages, poor working conditions and difficulty in raw material procurement and selling of finished products. And also they face stiff competition from power loom which can easily imitate the design and can make the same design in less time. Weavers need to be enabled to interpret designs and technical advancements, convert them into final product within stipulated time. Here comes the importance of entrepreneurial skills. The modus operandi in handloom market has three important pillars namely individual weavers, Master Weavers(Grihastha) & Gaddidars(Mahajan).The individual weavers work under master weavers who owns the paraphernalia for weaving but depends on Gaddidars for the sale of the of the goods. These gaddidars act as the middlemen and take up the profit by making a markup of 50% and then big retailers again make 50% markup on that which makes the price almost 100% more than the original price. This paper mainly focuses on the working model of entrepreneurs in handloom sector of Varanasi, here it refers to the master weavers. These weavers manage to keep themselves relevant and are able to create a market for themselves in spite of this sector being low technology driven. The entrepreneurial functioning in this sector is quiet an interesting thing. Government also is working tirelessly in promoting this sector, by implementing various schemes for benefit of weavers. The handloom products have their uniqueness in terms of their sophisticated designs. The master weavers often get an advantage by maintaining a low transaction cost and social capital. This paper will outline the working model of entrepreneurs/ master weavers and will also give an insight to the interventions of the government which will act as a catalyst to promote entrepreneurial functioning in individual weavers. The Government intervention through various schemes will help in educating weavers about technical as well as managerial matters and enable young weavers to enhance Entrepreneurship, Management and Computer skills and sensitize them on issues of Quality Control, Packaging, Zero defect and Zero effect apart from some component of technical knowledge so that they successfully emerge as Handloom Entrepreneurs. This effort is quiet apparent due to launch of BRAND HANDLOOM and providing e-commerce platform for the handloom products in collaboration with flipkart. Introduction of various courses in institutions such as IIHT is also a favorable step in this area. This paper will describe in detail about already existing model of entrepreneurship and efforts generated by the government in this direction. The main objective is to highlight the functioning & relevance of master weavers and their roles in value chain of handloom weaving, along with importance of government interventions which bases it schemes more or less on functioning of master weavers.

Keywords : Entrepreneurship, handloom industry, bootstrapping, marketing, master weavers, government schemes.

Indian industry is one of the important constituent Indian economy and acts as an stalwart in the country's economy. It contributes about 14 percent in the industrial production and 2 percent in the GDP. Handloom contributes around 15 % in total textile production out of which 95% products are exported. Thus, the growth and all around development of this industry has a direct bearing on the nation’s economic strength. Post economic liberalization, handloom industry witnessed major changes .There was move towards technological advancement i.e. power looms. The handloom weavers began to face the brunt when the designs were imitated and same designs were made in much less time. But the master weavers (entrepreneurs) were able to sustain their working model .

Varanasi being rich in cultural heritage is an important the center of Handloom silk production. The designs and motifs used in weaving such as kalga, bel, jhallar have their origin from Mughal era. The intricacy of this art is evident from the fact that it takes around 10-15 days to complete one saree. This art of weaving is centuries old which evident from history. Varanasi Handloom silk industry is basically dominated Momin Ansari. Weaving is mainly done by weavers belonging to this community. The marketing and whole sale activities is mainly controlled by Marwari/Aggarwal community.. But from last two decades the handloom market facing is many problems related to production and market. There have been fewer changes due in production process and major changes in market which let to change in the social structure of this industry . Master weavers are ones who employee around 10-15 individual weavers who carry out all the weaving and related activities. Gaddidar/Mahanjan (middlemen) they control all marketing related activities of handloom in the Varanasi. Due to the recent changes in the social structure of handloom industry, Individual weavers working under master weavers are facing problems of poor wages. One of the largest family- based traditional industries in India is handloom. The survival and relevance is contributed by government support and also by the ability of this sector to adapt to the changes and needs of textile industry. Handloom industry is making its hold in market rather high end market due to its uniqueness in designs and creation in spite of competition from power loom. The epicenter for this are the master weavers (entrepreneurs).Individual weavers prefer to work under the master weavers as they get the continuous flow of work.

Suresh Bhagavatula (2012): the paper tilted as "The Working of Entrepreneurs in a Competitive Low Technology Industry: The Case of Master Weavers in the Handloom Industry" studied the importance of transactional cost and social capital in low technology driven sector such as handloom. The study was conducted in Andhra Pradesh and operational model for handloom entrepreneur was derived and their position in handloom value chain was determined.

Shaw Tanushree (2015) has highlighted the present situation of weavers of varanasi and tried to define the role of master weavers as an enterprenuer. The paper shows the role of various stake holders in handloom production.

Om Prakash Raja (2017) has conducted a study on existing business model for handloom industry of varanasi. He has concluded that there has been lack of professionalism in this sector as this sector has been a traditional one. There is no proper business model as such and this profession is more of a family business.

Rajkishor Meher (1995) : the paper titled on “The Handloom industry and the socio-economic conditions of weavers in Orissa” studied the socio economic conditions of handloom weavers out that lack of proper government intervention this sector is losing its occupational value and popularity The weavers find it difficult to earn their living by this occupation. Lack of education among the weavers further worsens the situation. The weavers’ co-operative society at the village level is under the control of feudal capitalist system

Mukund, K. and Syamasundari, B. (2001): analysed the problems faced by primary handloom weavers societies. The major issues were found to be lack of financial and marketing assistance from government. Poor supply of yarn(raw material).

Mamta Chaudhary etal(2015): studied aboit the problems being faced by handloom & powerloom weavers in Uttar Pradesh and observed that there is lack of basic facilities for weavers. Lack of ,adequate supply of raw materials, outdated loom technology, no proper financial aid to the weavers .The other hindrance is due to lack of awareness about the government policies.

1. To study the entrepreneurial operational model by the handloom industry in Varanasi.

2. To study the Government Intervention facilitating the Handloom Entrepreneurship.

RESEARCH METHODOLOGY : Descriptive study is being conducted in order to analyze the situation. Individual & Master weavers were contacted for this study and case studies were framed after a discussion with them. The area for the study was Ram Nagar.

.This section would give detailed description about the operational model being followed by the handloom weavers. This would include the process such as starting up of the business, followed by production and then marketing of the finished goods.

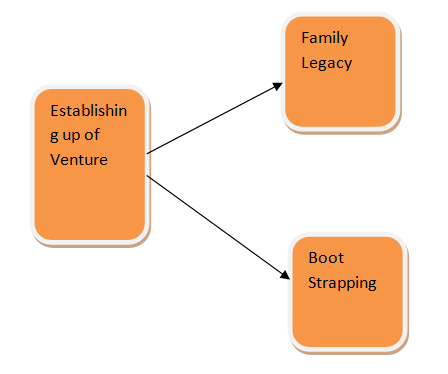

4.1 Establishing up of the venture :

There is no set of protocols for starting up of the business in weaving. There are similarities between the master weavers working styles in the cluster. And others who want to enter into this domain simply follow the same route. Fig 1 depicts the two ways in which weaving firm can be established.

There are basically two major approaches being followed in establishing a weaving firm.

1) The first one is the "Family Legacy: which is being inherited and carried out from one generation to another. Here in the members of the family only carry out all the roles and responsibilities. It becomes more of a family business and the siblings only start performing the duty of managers, when the business expands gradually all the stake holders get their share in the business. In other words the business gets fragmented into many firms.

2) The second approach is when an individual weaver who after working under a master weaver or NGO or cooperative start their own firm. They usually get the financial help from friends & family."Bootstrapping" concept of entrepreneurship works quiet well in this industry, where the master weaver sets up a firm with minimum capital.

Fig 1: Ways to Entrepreneurship

Managing a master weaver firm requires inferred knowledge that is accumulated by a concoction of experience and sense of belongingness. The basic difficulty in starting own firm lies in raising the capital and recruiting the individual weavers. Since most of them would already be working under another master weavers firm. The macro environment also impacts the establishment of the firm. During boom time, when the economy is optimistic the individual weavers can easily raise capital and suppliers of raw material are also willing to help with yarn supply and money. But during the contraction or when there is a slowdown in economy the situation becomes adverse for the weavers who want to establish their own firm. There is difficulty in getting the credit and raw material.

4.2. Operational Mode:

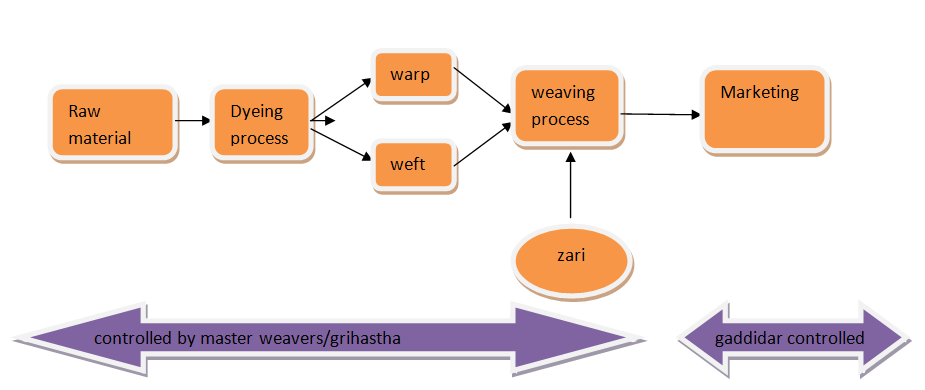

This business is usually managed from home where there is a separate space in the house itself for the business related activity which is called KARKHANA. Here all the weaving process is done and also the raw material is stored. The two component of operation is – Production (actual weaving) and Marketing (of finished goods) . . The clients of the master weaver are the owners and are called the Gaddidars (Mahajan) who act as the middle man between the master weavers and retail store owners. They are the ones who take the maximum share of the profit.

Handloom weaving is done by interlacing two sets of yarn, warp and weft. This is done without the use of electricity. Hand weaving is done mainly on Pit Loom, Stand Looms and Frame Looms. Yarn is the raw material used for weaving. Hank yarn is typically used for handloom weaving which is 840 yards long. For production yarn is color dyed in hank form only. Natural and chemical colorants are used to dye the hanks. Pre-loom activities such as Dyeing, Sizing the warp are done by the women and children. Attaching the warp, weft winding & weaving activities are carried out by the weaver. Post-loom activity includes bleaching, printing, calendaring and finishing. These activity is again carried out by the women and children. The individual weavers are paid the wages which is called as Bani .It normally takes around 7- 10 days to weave a sari on handloom. The design is given by the master weavers. The master weavers often carry out the production saris on contract basis. These contracts are given by the Gaddidars who actually control the market. At fewer times the master weaver carries out the production without any prior contract from Gaddidars and sell out the finished goods after the production is completed. The wages of the individual weavers depends on the complexity of design and ranges from Rs.100-250, which is not sufficient to meet the basic needs also. As they get maximum work only during festive seasons and wedding seasons. As Banarasi sari is still able to make a space for itself in wedding trousseau.

The entire production process is carried out in the household of master weaver and is called as Kaarkhana. Under his supervision around 10-15 individual weavers work. The individual weavers are paid the wages ones they complete the weaving of the saree. Their wages depends on complexity of design. The design and pattern which needs to be weaved is communicated to them by the master weaver. The master weaver maintains a ledger where he records the dealings with his weavers and Gaddidars. The individual weavers retain & maintain their creativity because even when designs which are to be made are communicated to them, there is always some space for their creativity. The master weaver who work under the Gaddidar get the Raw material for production from them only. On the other hand master weavers who work independently they procure the raw material on credit basis. Here the real challenge of master weaver comes into light. They have to strive hard to maintain the continuous flow of work from gaddidars and credit of raw material if working independently. Since they have individual weavers working them who in case do not receive the wages can flock to other master weaver's kaarkhana. And many weavers are working as contract weavers under multiple master weavers.

Here the concept of Social Capital and Transactional Cost comes into action.

Master weaver keep themselves prominent & relevant by keeping low transaction and social capital. They sweat in lots of efforts to extend the credit periods from raw material supplier. In case where they work independently where they get raw material from Gaddidars, they pay wages to the individual weavers in chunks. When we talk of social capital, the master weavers use their social networking for carrying out the business. They have a rugged networking among all the stake holders such as clients, Gaddidars and individual weavers. Sometimes if they get to interact directly with the client, they stock the finished goods as per the requirement of the client without the involvement of Gaddidar. They directly sell the products to the clients. This networking also plays important role in getting the expert weaver to work under them. For some specific and unique designs where more of articulate skills are required, weavers with high creativity are sought after. They can be traced through referencing and liasoning. The master weavers delay the payment of wages with the help of their strong ties in the community. Diagrammatic representation of the value chain is depicted in Fig.1 where all the weaving related activities such as pre loom and post loom are controlled by Master Weavers and Marketing related activity are under the ambit of Gaddidars (Mahajan).

Fig.2 VALUE CHAIN OF HANDLOOM WEAVING

The main clients are the retail store owners or the wholesalers. The individual buyers either buy the products from retail store so from the wholesales too. The Gaddidars are act as the middlemen who get the finished products from master weavers and then sell it to the retail stores and whole salers. The gaddidar sell the products at around 50% markup price and the retailers sell this at 50 % mark-up. So the products that are available in market are around 100% overly priced. The master weavers keep visiting the gaddidars for the payments. During festive seasons they are able to get the payment easily while things are difficult during slump period. Again during the period of slump the social capital comes in for rescue, it helps the master weaver to get access to raw material and cash flow through networking and liasoning. So he has to make a maintain a balance between these two phases to keep intact the weavers working under him and gaddidars. Sometimes the Gaddidars delay the payment until the all the products are not sold .Therefore a regular follow up has to be done.

Master weavers remain relevant for two main reasons. First by maintaining the low transactions cost and second by tactfully using the social capital as this sector is highly labour intensive so social interaction and networking comes plays a very important role. Regular interaction with all the stake holders and close proximity to the market are key to survival.

7.1 Keeping the transaction costs low:

Some of the ways in which the master weavers keep the transaction cost low are:

1).Delaying the payment to the weavers working under them.

2).Bargaining for longer credit period from raw material suppliers.

3).Hiring the individual weavers on contract on temporary basis, those weavers who work under multiple weavers are contacted. In other words they work on the principal of bootstrapping.

7.2 Social Capital:

In this low technology driven sector the weavers act as the main asset for the firm. They are the skilled workers who create the final hand woven product. There is a fierce competition as all most all the weavers are highly skilled in this art of weaving. So the key to success lies with the person who has better understanding of the market information. Here social networking plays crucial role. The master weavers with his liaisoning skills should gather information about the designs and patterns which are in vogue. The social contact with the retailers and clients can help to gather this information. These important inputs helps the master weavers to keep a pace with external environment and thus the success of his firm. The market information if processed properly can help to make the products as per needs of the market.

Many a times when there is slum in market, the business is adversely hit then the recovery becomes even more difficult. Master weaver has to wait till his products get sold in the market for this due payments, which happens only after improvement in market situation. Due to lack of awareness about the technological advancements these master weavers are not able to use the e-commerce platform for selling of their products. This again is due poor literacy rate in weaving community.

The marketing information is disseminated on the basis of informal relationship among the weavers. They extract the information from the fellow master weavers or suppliers of raw materials and also from gaddidars. They also try to visit the stores to themselves find out the footfall in the peak hours, during festive season and off season too.

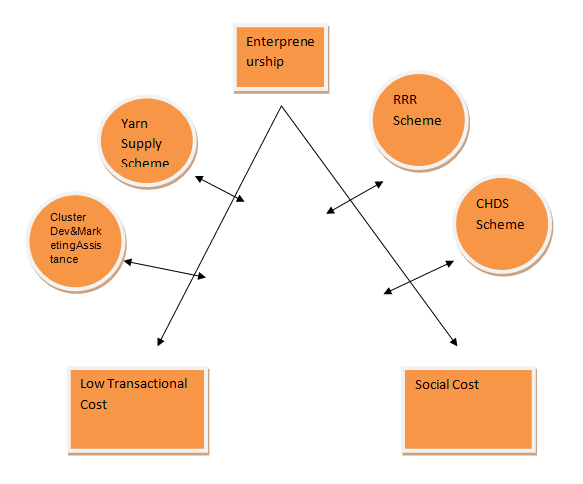

Two important factors contributing to the entrepreneurial success of master weavers are found to be low Transactional Cost and Social Capital. There are various government schemes too which act as a catalyst and helps in reducing this cost. Transactional cost can be lowered by Yarn Supply Scheme, National Handloom Development Program(formed after merger of RRR and Comprehensive Handloom Development Scheme).The benefits of these schemes and how this step is helpful in promoting entrepreneurial skills in master weavers is explained below. 1. National Handloom Development Program: Comprises of two schemes namely- Revival, Reform & Restructuring and Comprehensive Handloom Development Scheme.

1a)Revival,Reform & Restructuring :Under this scheme Govt had sanctioned Rs 3884 crore for development of handloom sector which also included opening of 39 Apex Weavers Cooperative Societies, 9642 Primary Weavers Cooperative Societies(PWCS) and 6310 Self Help Groups. Loan waiver and forms an important part of this scheme. Concessional credit is given to weavers where margin money is upto Rs.10,000 and loan is sanctioned at 6% interest rate .Weavers are given Weavers Credit Card under this scheme.

1b). Comprehensive Handloom Development Scheme : It has several sub components and plays very crucial role for development of this sector. The main aspects includes:

i).Cluster Development : under this scheme new cluster development is promoted along with consolidation of existing clusters. For consolidation financial assistance is being given by the government. In 11 plan Rs 50 lakh and 20 lakh respectively was sanctioned for clusters having 5000 handloom per cluster and 300-500 handlooms for 2 years time frame. Some handloom weavers who are not covered in clusters are being given support with help of "Group Approach". On an average Rs.30000 per weaver is sanctioned and a group of 10-50 weavers are assisted for technology up gradation and construction of work-sheds.

ii).Block Level Common Facility Centers : In varanasi 9 common facility centers(CFC) have been made under this block level cluster approach. These CFCs have yarn depots, internet facility, other facilities too related to weaving such as winding/warping/Dyeing. For design support Weavers Service Centers are there. There are technically qualified staff for all the steps.

iii)Handloom Marketing Assistance : Development and promotion of marketing channel is the main objective of this scheme. It is applicable for domestic as well as export market. The main aspects are organization of craft melas, exhibitions, e-marketing, promotion of "handloom mark", ,Geographical Indication of Goods, International fairs and exhibitions.

· E-Marketing-In order to promote e marketing, Government has signed Mo U with Flipkart ,so that handloom products can be purchased online too.

· Handloom Haat-These are permanent marketing complexes in order to provide infrastructure for marketing the handloom products. There are retail outlets and exhibitions are also organised to give a platform to weavers for show casing their skills.

iv).Development & Strengthening of Handloom Institutions : Indian Institute of Handloom & Technology and Weavers Service Centers are the institutions which are present for skill up gradation of this sector. National Center for Textile Designs was established in 2001 in order to keep pace with the changing demands in design of the handloom products.There are 6 IIHTs controlled by Central Government and 4 by State Government. They all conduct 3 year diploma in handloom technology. Campuses in Varanasi and Salem conduct post diploma courses too. In dec 2015 B.Tech in Handloom Technology has been started in Salem campus. The courses run in these institutions inculatates the knowledge regarding deals fabric structure and cloth analysis, weaving theories and fabric calculations, textile chemistry, dyeing and printing, textile designing with help of computer, quality control, marketing management etc. There are certain cerificate courses too launched in year 2015-16 in Varanasi, Salem and Bargarh which is acting as building block for the youth of handloom weavers families for development of technical skills for production with ‘zero effect and zero defect’. A certificate course on “Handloom Entrepreneur” has been launched which will cover technical& management related aspects. This will equip weavers with entrepreneurial & managerial skills along with knowledge of computer. This will also provide information regarding importance of quality control, packaging.

· India Handloom Brand- was launched on Aug7 2015 in order to endorse the quality of handloom product and promote the zero defect and zero impact policy. The launching of this brand will help in ensuring the production of quality products with unique designs and making its reach in customers.

2.Yarn Supply Scheme -This scheme is helps to make available all types of yarn to the weavers at Mill gate price, so that there is continuous flow of raw material. This helps the master weavers to easily procure the raw material and do not have to depend upon the credit. The freight charges are reimbursed under this scheme.

Fig 3: INTEGRATION OF GOVERNMENT INTERVENTION WITH ENTERPRENEURIAL OPERATION:

Most of the master weavers follow the mode of the operation including transactional cost and social capital. The weavers still feel the need for the support from the government for the entrepreneurial activity. Off late due to so many schemes launched at regular interval ,weavers feel motivated towards taking up this venture. Earlier it was more of family legacy but eventually more new individual weavers are moving towards entrepreneurship. Some of the weavers were not able to start anything on their own due to lack of credit and marketing facilities. Few Government schemes are there which specifically address these issues. Weavers in general feel the lack of awareness towards these schemes. If properly implemented these schemes will boost the entrepreneurial activity in this sector.

The Master weaver firms have acted as back bone of handloom industry ever since. Still there are not enough literature on working models being followed by these private entrepreneurs. They provide lively hood to so many individual weavers, but they are often criticized of paying low wages to them. If the operation of this industry is looked into, it can be easily be seen that master weavers face a lot if difficulty in raising capital to carry out daily production. Everything is so much dependent on credit system. They have a little say in marketing of the products as much of the activity lies in hands of Gaddidars (Middle men).They release the payments once they receive it from the big retailers. Keeping the this industry so much relevant and keeping the pace with changing market trends is largely contributed by these master weavers. But now due to government interventions in form of various schemes these entrepreneurs are getting benefitted. As most of the schemes are acting as facilitators in removing various hurdles being faced by master weavers such as making easy raw material supply, providing marketing assistance etc. The need of the hour is to increase the awareness about these so that maximum benefit can be availed. Sustenance of this entrepreneurial model can be fuelled by the government schemes.

CASE STUDY :

1. The respondent belongs to the Ram Nagar block of Varanasi and is working as Master Weaver. He and his family has been actively involved in the weaving from past generations. According to the respondent "weavers identity card" helps them to get 10% subsidy on raw material. He purchases raw materials from the CFC (Common facility center -Ministry of Textile). But other important raw materials like Zari silk has to be purchased from the local market because it is not available at CFC. He is able to get raw material from suppliers easily and can make payment even after 10-20 days. He is able to get designs from designers appointed by government at different clusters. The respondent sells the finished goods to CFC & gaddidars both. Respondent was also aware about the government schemes as he frequently visits handloom offices of government and also has a card provided by the CFC.

2. The respondent has around 30 weavers working under him and is working as master weaver. Earlier he was working as individual weaver which helped him develop his social networking. Due to which he was able to establish his own venture. He raised funds from the local market and other people already working in this business. The individual weavers working under him get the wages for their work and he provides them with raw material & designs. Weaving work is done at his premises and is called kaarkhana. He gets raw material from the NHDC (national handloom Development Corporation) and gets 10% subsidy. For purchase of zari, he has to approach local market. The local raw materials suppliers generally charge 2% interest on credit purchase. The entire process of weaving according to him works with the support of local suppliers and government schemes.

3. The respondent is a master weaver and inherits this business from his ancestors. He has witnessed lot of changes in the market. He is able to get the designs from the NIFT designers appointed by the government in each block. He says Government of India trying to help the sector through the raw materials, designs, and marketing. Also now he is able to sell his products in various exhibitions organized by the government. There are 10 weavers working under him and wages are being paid to them in the range of Rs 150-250.

4. The respondent was working as individual weaver under Master weaver. He got the Mudra Bank loan and started own production with help of 4 handloom machines. He now has employed 10 weavers under his supervision. The respondent purchases raw materials from the CFC and avails 10% subsidy on that. If purchases of raw material are made from local suppliers, he gets relaxation in payment without any interest. This is possible due to social network and referencing. But there is delay in payment from the gaddidars. They release the payment only when the products get sold which usually takes couple of months.

5. The respondent belongs to Ram Nagar area. and is involved in weaving from generations. He is now working as the Master Weaver. He has the two Handloom production units . According to the respondent, he has the weaver identity card and gets yarn from the CFC at 10% subsidy and also purchases raw materials from the local supplier. He gets raw material from local suppliers on credit basis because of good social contacts. He gets designs from designers of the government office located in each cluster. The wages of weavers working under him depend on the complexity of the designs. He sells his product to the traders(gaddidars) without any documentation. The entire transaction is carried out on basis of mutual trust and social networking. But now there is change in the trend, the traders have started keeping the records in their ledger book. He keeps participating in various exhibitions and craft melas organized by the government at regular intervals which helps him understand the market well. His children are involved in marketing activity. According to the respondent the handloom sector will sustain with support from government. In order to remain relevant it is very important to explore the market and keep oneself updated with government schemes.

Adler P.S., and S.W. Kwon. (2002): “Social Capital: Prospects for a new concept”, Academy of Management Review , Vol. 27, No. 1, pp. 17 - 40

Bagchi, A.K. (1976): “De-industrialization in India in the nineteenth century: some theoretical implications”, Journal of Developmental Studies, 12, 134 - 165

Burt, R. (1992): Structural Holes – The social side of competition, Harvard University Press, Massachusetts

Cable, V.I. Weston, A. and L.C. Jain (1986): The commerce of culture: The experience of Indian Handicrafts , South Asia Publications.

B. Sahoo (1993). Problems and Prospects of Textile Industry. New Delhi: Mittal Publications, p.154.

Rakhin, K. V. (2015). Traditional Handlooms of India: The Role of Designer into Market Opportunity Recognition in the Globalization.

Ramachandra Chatty, S. (2016). Survey on Impact of Traditional Handlooms Schemes:A Case Study at Madhya Pradesh, India. Research Journal of Management sciences , 9-12.

Clingingsmith, D and J.G. Williamson (2008) “De-industrialization in the 18th and the 19thcentury India: Mughal decline, climate shocks and British industrial ascent”, Explorations in Economic History, 45, 209 - 234

EXIM Bank (2000): “Indian Handloom: A Sector Study”, Occasional Paper No.79 .

Granovetter, M (1973): “The Strength of Weak Ties”, American Journal of Sociology 78(6): 1360 – 1380

Harnetty, P (1991) “De-industrialization revisited: the handloom weavers of the Central Provinces of India c. 1800 – 1947”, Modern Asian Studies, 25, 3, pp 455 – 510

Jack, S. (2010): “Approaches to studying networks: Implications and Outcomes”, Journal of Business Venturing, Vol. 25, 120-137

Jain, L.C. (1985): “1985 Textile Policy: End of handloom industry”, Economic and Political Weekly , 6 July

Kirzner, I. (1997): “Entrepreneurial discovery and the competitive market process: An Austrian approach”, Journal of Economic Literature, XXXV: 60 -85

Long, N. (1968): “ Social Change and the Individual: A study of Social and Religious Responses to Innovation” , Manchester University Press, Manchester.

Marx, K. (1853): “ The British Rule in India” , New York Daily Tribune, June 25th

Meher, R. (1995): “The handloom industry and the socio-economic conditions of weavers in Orissa”, Journal of Rural Development 14 (3): 301–322.

Mooij, J. (2002): “Welfare policies and politics: A study of three governmental interventions in Andhra Pradesh, India”, Working Paper No. 181 , Overseas Development Institute, London

Mukund, K. and Syamasundari, B. (1998): “Doomed to fail? Handloom weavers; cooperatives in Andhra Pradesh”, Economic and Political Weekly 38 (52): 3323–3335.

Mukund, K. and Syamasundari, B. (2001): “ Traditional industry in the new market economy. The cotton handlooms of Andhra Pradesh ”, Sage Publications, New Delhi

Srinivasulu, K. (1996): “1985 Textile policy and handloom industry. Policy, promises and performance”, Economic and Political Weekly 7 December 22

Srinivasulu, K. (1997): “High-powered committee, low voltage report. Mira Seth report on handlooms”, Economic and Political Weekly , 14 June

Ramaswamy, V. (1985): “The Genesis and Historical Role of the Masterweavers in South Indian Textile Production”, Journal of Economic and Social History of the Orient, Vol. XXVII, pp 294 – 324

Roy, T. (2002): “Acceptance of innovation in early twentieth-century Indian weaving”, The Economic History Review, Vol. 55, No. 3.

Textile Ministry. (2002): Annual Report 2001-2002, http://texmin.nic.in/annualrep/ar02_con.htm accessed 10 June 2009